Cody James - EnvyUs Garage - S4. Ep39

Listen Here!

Definition of Built not Bought

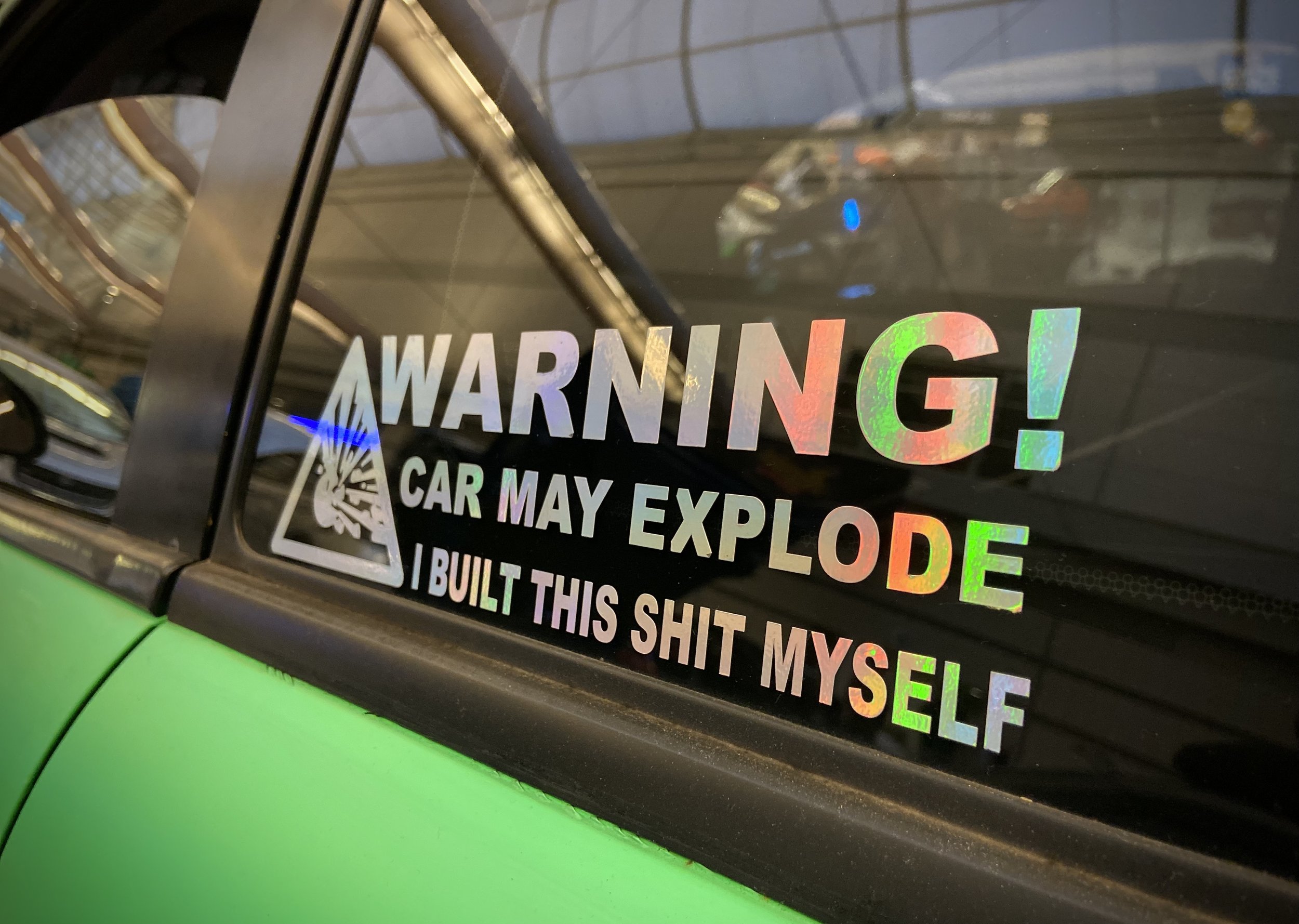

Since the inception of the podcast I have been searching for people to highlight with real budgets and real skills that represent what you will see at a typical car show or cruise. The journey of learning how to fabricate and build an entire car is a monumental task but when done is one of the most rewarding exercises. For Cody James his daily driver Cobalt SS turned street/strip beast was built 100% at home out of boredom and to prove to his friends it could be done well and on a budget. The sticker on the side of his car is not only a metaphorical disclaimer but in every sense of the meaning, absolutely true. The car was built on blocks in a three car garage and is the only RWD Cobalt that still retains the unibody platform.

To start, the Cobalt SS was GM's introduction into the tuner market and in a 2013 review, journalist Patrick George called it the best compact car ever made by General Motors, and a potential "future classic. To be honest, I think this still holds up, when is the last time you saw a Cobalt SS at your local car show, or just cruising around town? Available as a coupe only, the SS Supercharged featured the 2.0 L LSJ Ecotec engine with an Eaton M62 roots type supercharger and air‑to‑liquid intercooler. The engine makes 205 hp at 5600 rpm and 200 lb/ft at 4,400 rpm. GM offered dealer-installed performance upgrade packages called "stage kits" that were covered by factory warranty! The Stage 1 kit consists of new fuel injectors and a reprogram of the ECU, and yields a 30hp improvement. The Stage 2 kit consists of new fuel injectors and the same reprogram with a smaller serpentine belt and pulley for the supercharger, producing a 36hp improvement and 18 lb/ft of torque. Both stage 1 and 2 kits increase the engine redline to 7,000 rpm. The Stage 3 kit consists of a smaller, 76mm supercharger pulley, a 2‑pass intercooler end plate and a customizable replacement ECU. The Stage 3 ECU allows for the use of a 50‑shot of nitrous, 100 octane fuel and an adjustable redline from 6,750 to 8,000 rpm. Stage 3 produces 248 hp using 93 octane fuel, up 260 hp using 100 octane fuel, and much higher power with nitrous. Stage 3 is for track use only, and to emphasize this, air conditioning is disabled with the Stage 3 ECU. If you were to find a stage 3 in factory condition you’d have one rare bird!

However, Cody’s 2007 SS is none of these things and in fact resembles more of a classic drag car setup than the FWD boosted tuner it was originally built as! Cody acquired the car in 2012 from his father who originally bought it in 2010 as a gas saver. After driving the SS around as a daily driver in 2015 he was simply going to put a bigger supercharger but like many of us needed more HP than the supercharger could give. Turbos were the answer, however after some research and finding out the stock block could only handle about 550hp Cody changed directions again! With the help of ZZP Performance, he acquired a Gen 3 closed deck block which can be pushed to 898hp.

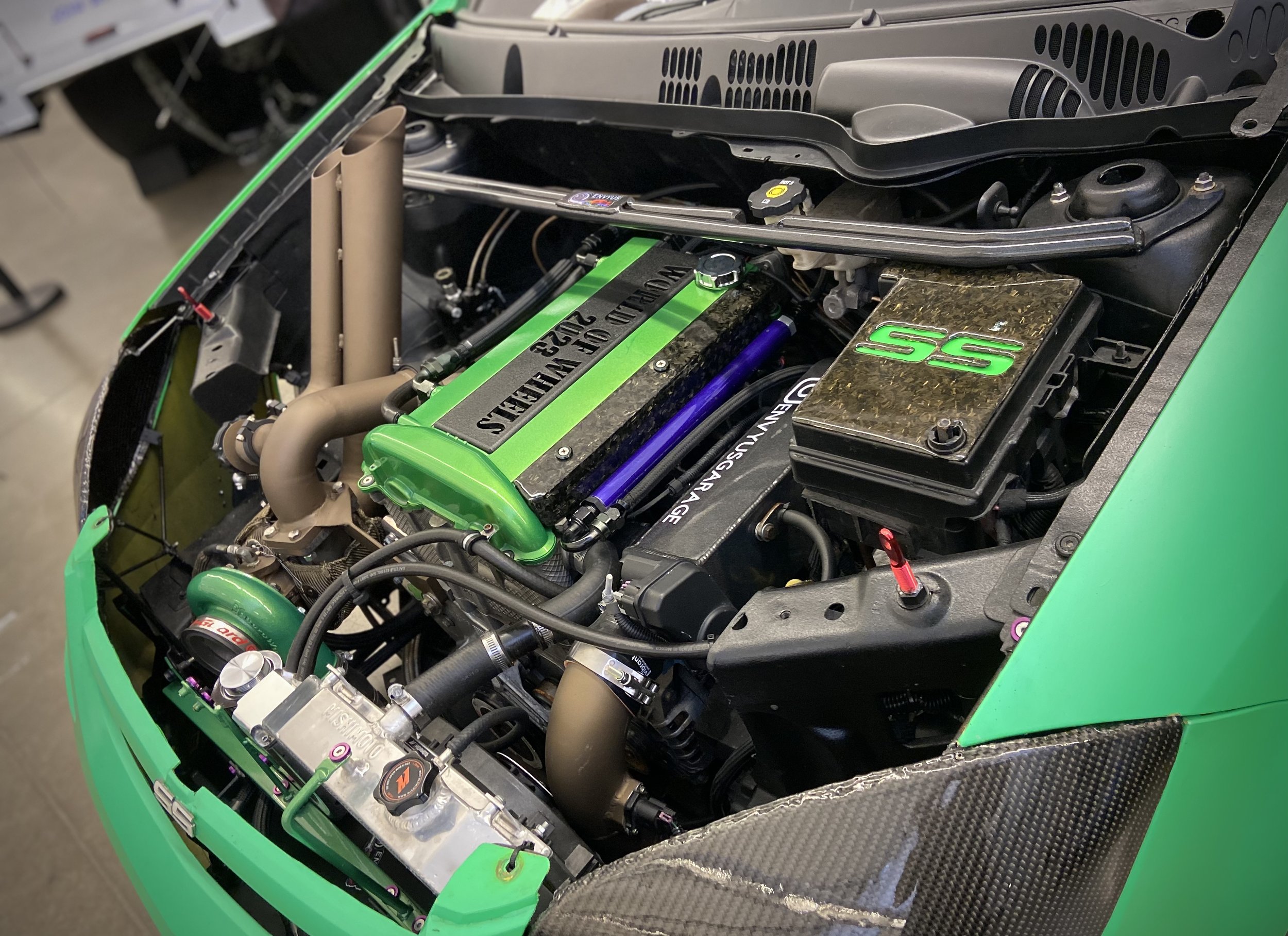

The first iteration of the motor, like the sticker on the side of the car says, literally blew up. When swapping out the main bolts, Cody did not have it line honed to precisely align the crankshaft in the engine block which in turn ruined the main bearings. Now on 15psi of boost the Borg Warner 257SXE helps get this motor into the mid 400hp range. Cody will be taking it to get tuned this summer to hit bigger numbers with an upgraded larger turbo. Right now it is good for a 1.6 60ft as Cody has only been concerned with launching the car at this point in its life.

While the first iteration of the motor was down, Cody knew that one of the weak points in the Cobalt platform was traction. He also knew that FWD would limit him with transmissions and engine spacing. Taking a page out of the old school drag race playbook he decided this Cobalt needed to be RWD. There are two known RWD Cobalts in the world, both of which are either tube chassis cars or a body dropped onto a RWD GM platform. Cody’s is the only one that remains on the Cobalt unibody. With the motor turned sideways it now sits on small block 350 motor mounts fabed to mate up to the unibody. While there are adapter plated galore to mate any motor to any transmission in our modern world, Cody found that a Pontiac Solstice GXP (also an under appreciated platform) was a direct bolt up! The twin disk clutch with the manual 5 speed gets all the horsepower to the rear end.

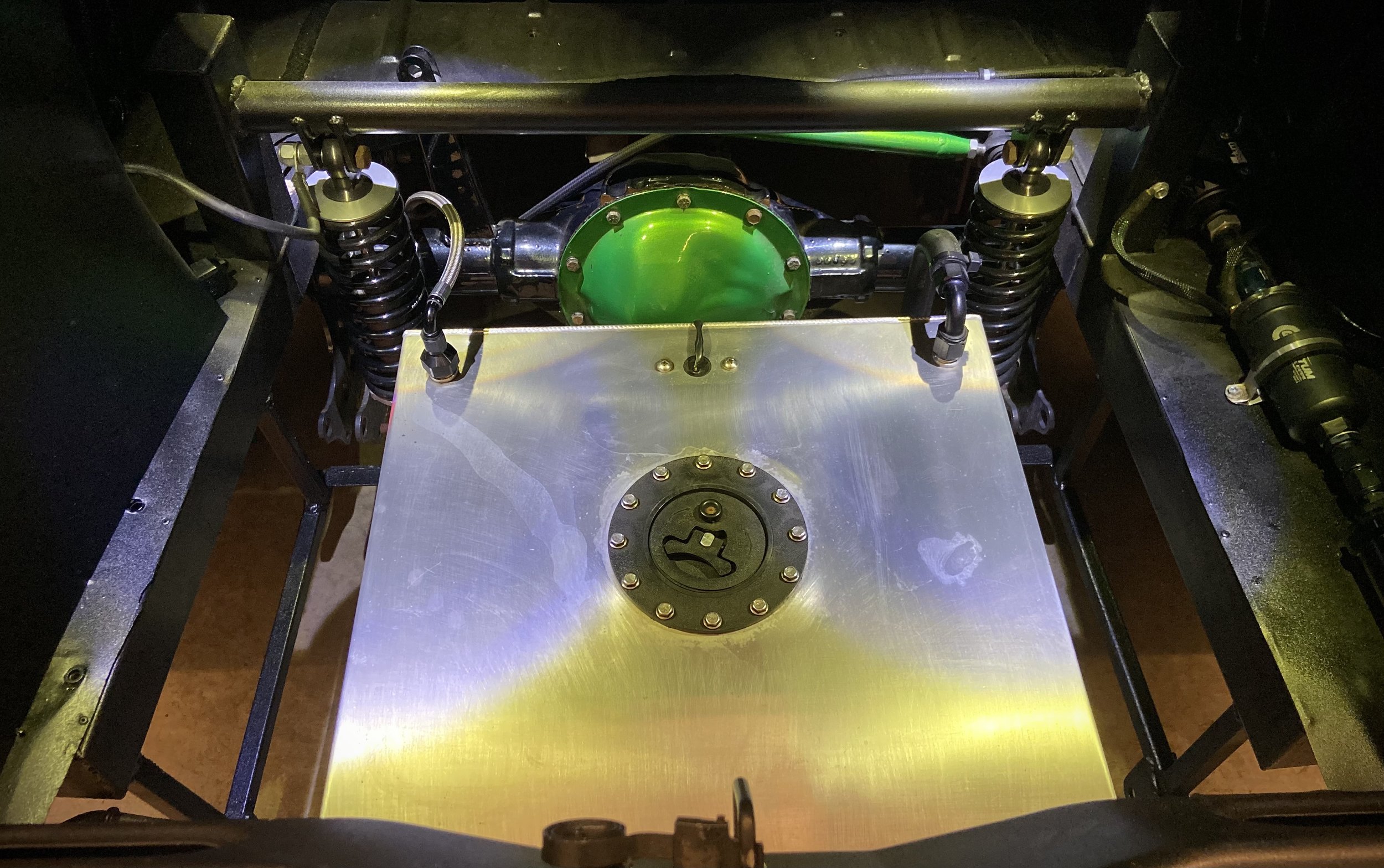

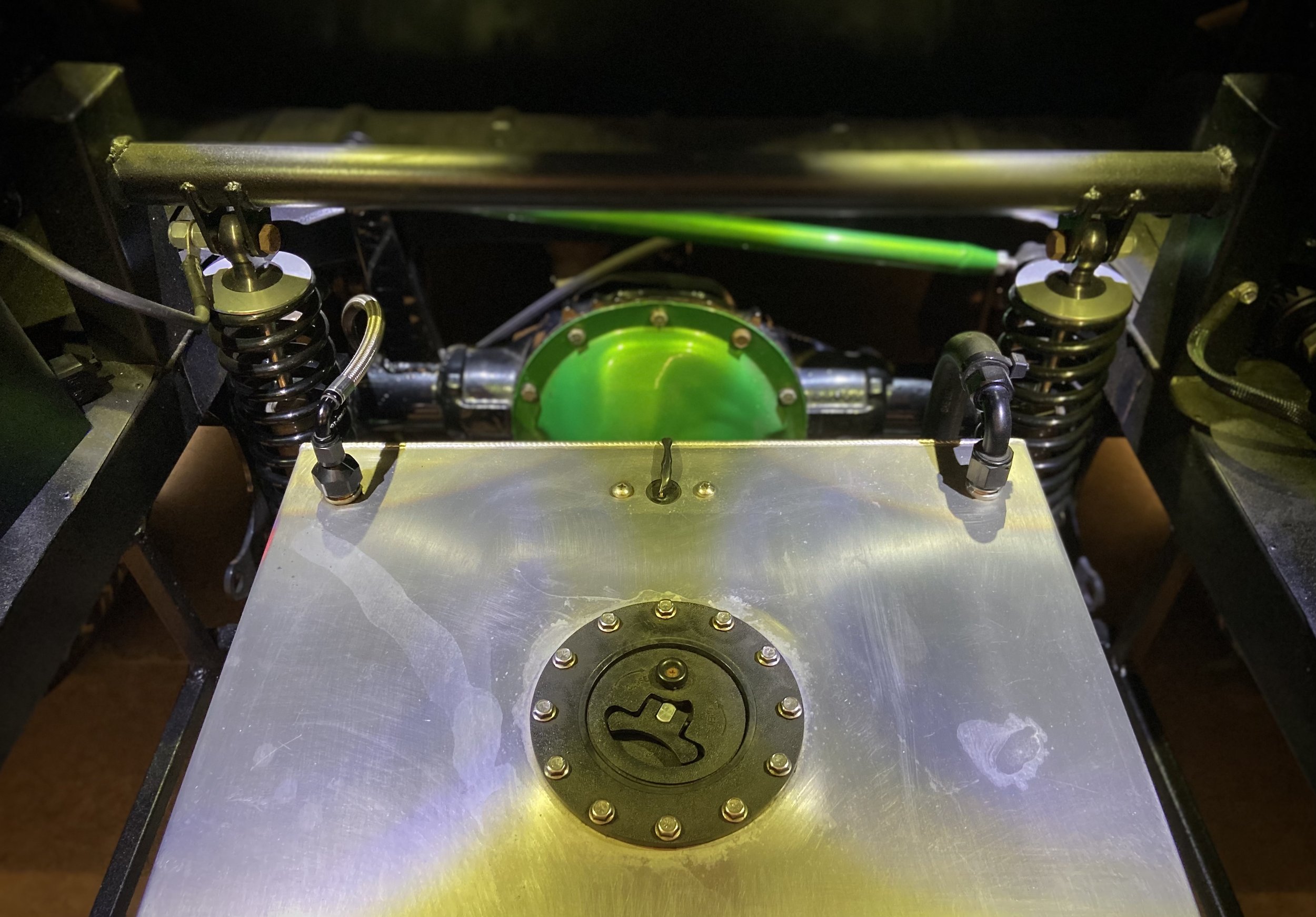

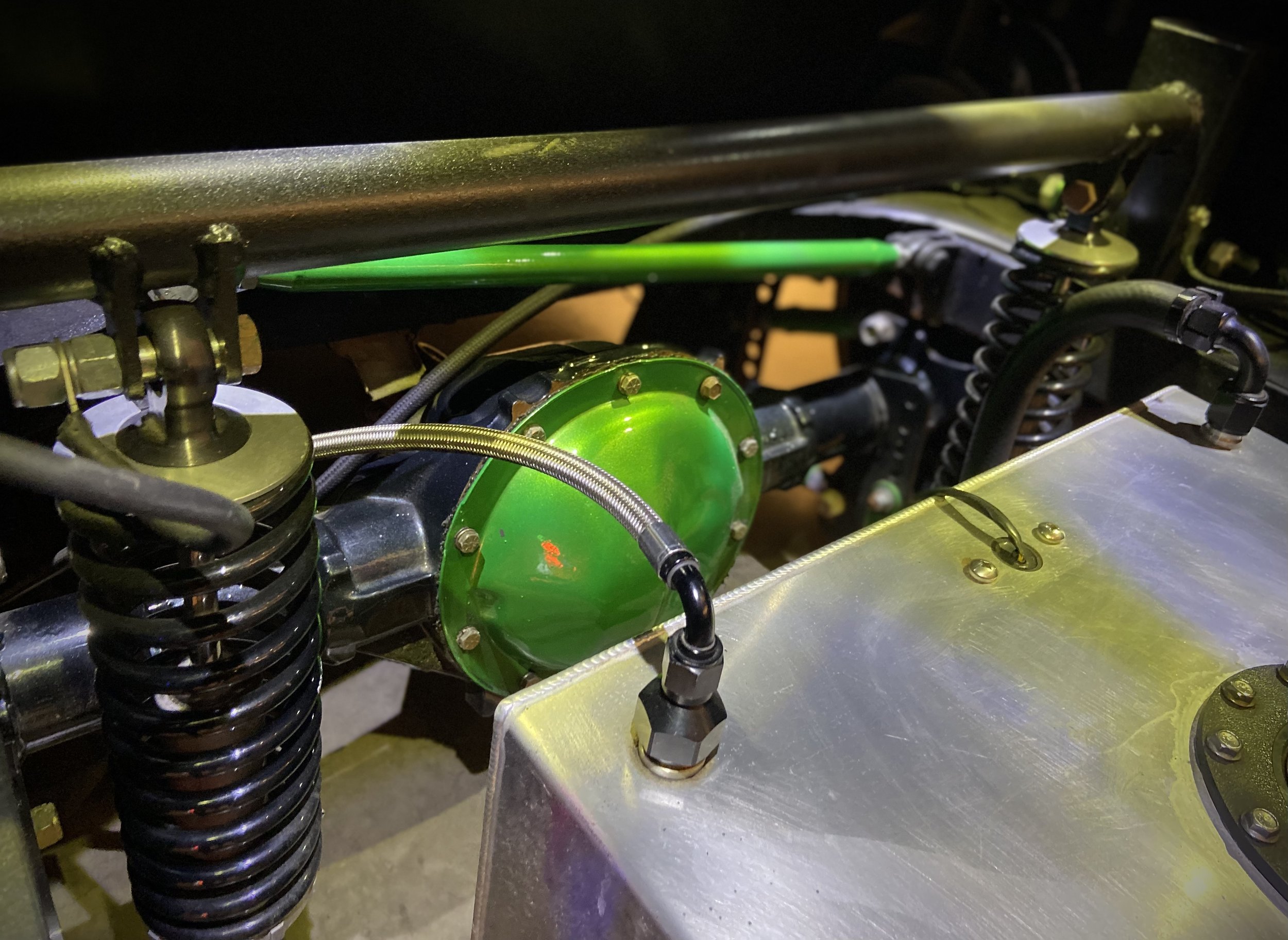

The original plan was to use the Solstice rear end with the independent rear suspension however Cody found he wanted to go a different direction. The Cobalt now has a piece of GM history sitting under it in the form of a 1968 Camaro 10 bolt rear end stuffed with 3.90 gears. The 10 bolt has a long proven history used in high-performance, high-horsepower applications. But for all intents and purposes, the 10-bolt rearend is a great unit for a street/strip car, and can be stout enough to handle the abuse delivered by use at the racetrack when upgraded. Cody reports that the 10 bolt is only 1/2” difference from the stock Cobalt wheelbase. Suspension is now handled by a 4 link for a Camaro with Competition Engineering fully adjustable coilovers that dials everything in for the strip.

The body while looks mostly stock has functional pieces all over it to maximize it getting down the strip. To start, Cody will never have an issue finding this car in the paddock or at a car show as the 3M satin florescent neon green wrap that was wrapped by Cody and makes the car pop! The custom carbon fiber pieces were all made by Cody that include the wing and headlight deletes. All of the powder coated and cerakoted pieces under the hood were all done in Cody’s three car garage. All of these tiny details makes this one of the nicest looking race cars, and as Cody says, “the appealing aspects of what people like to see but also have the functionality of a drag car.” The body mod that gives this thing the attitude is a wide body kit in the rear off of a Toyota BRZ that ensures your eyes go straight to those huge rear slicks.

The interior stays pretty stock minus the single racing seat and a harness bar. The plan for the interior moving forward is to gut it to lose more weight. This includes the door panels, interior panels, dash, package tray and any other piece that doesn’t serve any function to go fast. At this point in the Cobalts life its still a work in progress however the ultimate goal is a 9 or 10 sec car! Pretty crazy when you think about the original use of the car and that the name of the motor is EcoTec!

By day Cody works on a gas pipeline in operations for a transmission company. Cody’s other cars include a sweet 2015 Z51 Corvette, you can see in some of the background pics at the show, with a fully built top end called the “ChopNess Monster” that makes 550whp. He has two restoration projects in the form of a Datsun 260z and 1968 Camaro. Cody just finished an 89 Porsche 94 Turbo track car and a unicorn 07 Duramax LBZ single car, long bed 6 speed manual. If that wasn’t enough, he has an 86 square body C10.

Big thank you to Cody and the Burgh Built crew who all showed up to the World of Wheels! You can find Cody on instagram @envyusgarage or rolling around car shows or race paddocks in the Pittsburgh area. I can’t wait to see the next iteration of the build, like many of us the project is never complete and we want to see the Cobalt’s nose in the air and like Paul Walker, running under 10 sec!